Tuulevurr - selvedges and details

The new Tuulevurr blanket has a narrow border of rust running along its selvedges. One face is in ink with a pattern of fine oatmeal lines, and the other is reversed, with an oatmeal ground and the pattern in ink.

All of my blankets are reversible, and many have two quite different faces allowing you to ring the changes by simply turning the blanket over.

The reversible quality of the blankets has often left me with the dilemma of which way to fold the fabric at the edge for the traditional blanket stitch hem I usually use. This edge stitch detail which incorporates a narrow sewn-in label is the only visual indication of a hierarchy of ‘front’ and ‘back’.

With the Tuulevurr’s border detail running along either face, I was reluctant to fold the edge at all, and instead have left it unfolded, with the plain selvedge edge showing. The cut ends of the blanket are similarly secured with a simple fine stitch line, leaving all the edges as plain and discreet as possible.

The reversibility of the Tuulevurr is emphasized further with a little couched-stitch initial to the corner. The initials appear on each face, at diagonal corners of the blanket, leaving no sense of a nominal front or back. The blanket has a discreet label hand-stitched on the edge, but I like to hope that this might be snipped off by its new owner, leaving simply the initialed EP for a tongue-in-cheek ‘proof of provenance’.

I have always found selvedges interesting. Usually they do not show in a garment or finished piece, but where a full width of fabric is used or a selvedge edge is incorporated into a garment, they leave a satisfying sense of the weave process.

The images below are of my studio sampling loom - on the left you see the rust border in the warp threads before the warp is reeded; and on the right you see it appearing at the edge of the woven cloth.

The samples I weave in the studio all have a shuttle selvedge. Most hand-woven fabrics are made in this way, with the weft yarn wound onto a bobbin that sits in the shuttle.

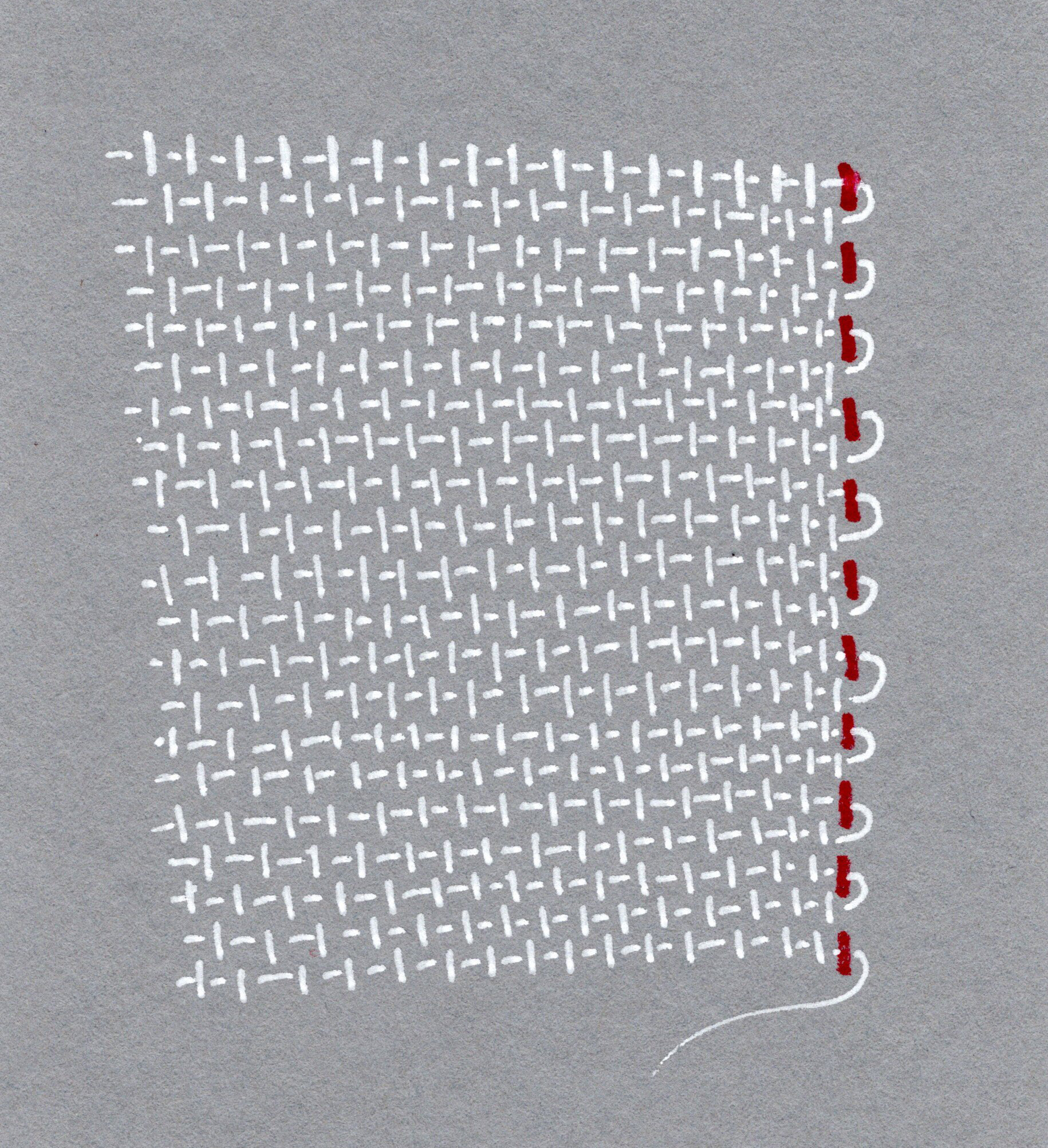

My little drawing on the left below, shows a detail of a plain-weave shuttle fabric. The warp threads run vertically, and the weft runs horizontally. The weft thread is continuous, snaking from side to side up the length of the fabric as it is woven. I have picked out the very edge warp thread in red.

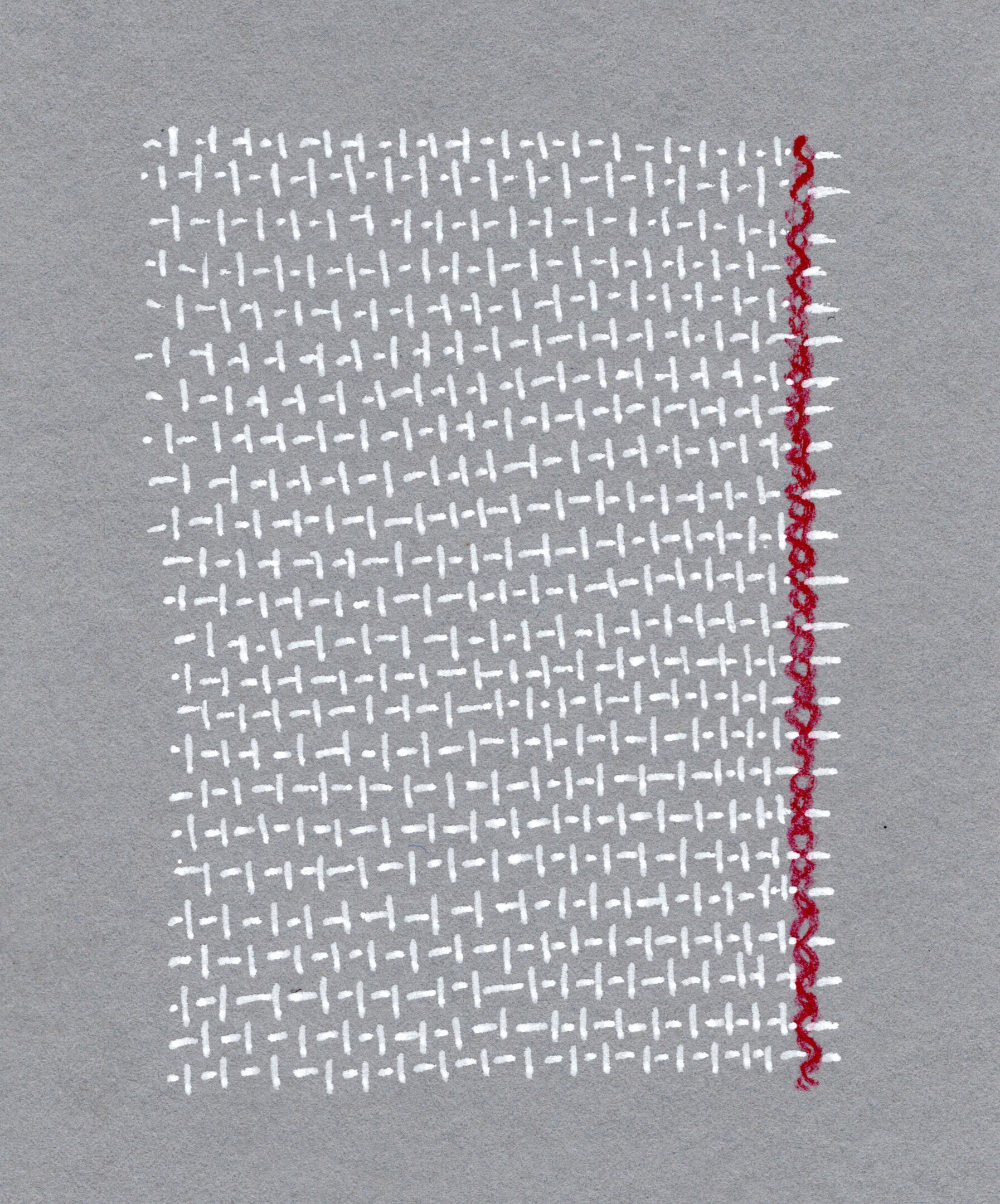

The production run of the Tuulevurr is identical in every way to my hand-woven sample, save for the selvedge edge. In production it is woven on a rapier loom, and has a ‘leno’ edge. In my little drawing on the right you see a detail of a plain-weave leno edge selvedge. Here the weft thread is cut at either edge of the fabric, making a short fringe along the selvedges. The selvedges are secured with a pair of very fine looping threads which wrap around the weft threads in a twisting figure of eight to hold the edges of the fabric firm. You can see these looping leno threads picked out in red below.

In the image below you see the Tuulevurr fabric in production on the beautiful Dornier looms at Mitchell Interflex. If you are familiar with industrial looms you will no doubt recognize the particular Dornier green. At the near edge of the fabric you can see the rust border and beyond it the neatly cut fringe.

For more about the palette and inspiration behind the Tuulevurr blanket please see the journal post here.